| Model | DXF-3 | DXF-4 | DXF-5 | DXF-6 | DXF-7 | DXF-8 | DXF-9 | DXF-10 | DXF-11 | DXF-12 | DXF-13 | DXF-14 | DXF-15 |

| Cooling Capacity* (kW) | 12 | 18 | 25 | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 170 | 220 | 260 |

| Rated Flow (L/min) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max.Working Pressure (bar) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 16 | 16 | 16 | 16 |

| Fan Power (KW) | 0.55 | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 3 | 3 | 4 | 2*2.2 | 2*3 | 2*3 | 2*4 |

| Inlet&Outlet Thread | G1" | G1¼'' | G1¼'' | G1¼'' | G1¼'' | G1¼'' | G1½'' | G1½'' | G1½'' | G2n | G2n | G2n | G2n |

| Thermometric Thread | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' | G3/8'' |

| Noise Level** (dB) | 62 | 66 | 68 | 75 | 77 | 80 | 83 | 87 | 92 | 85 | 86 | 92 | 98 |

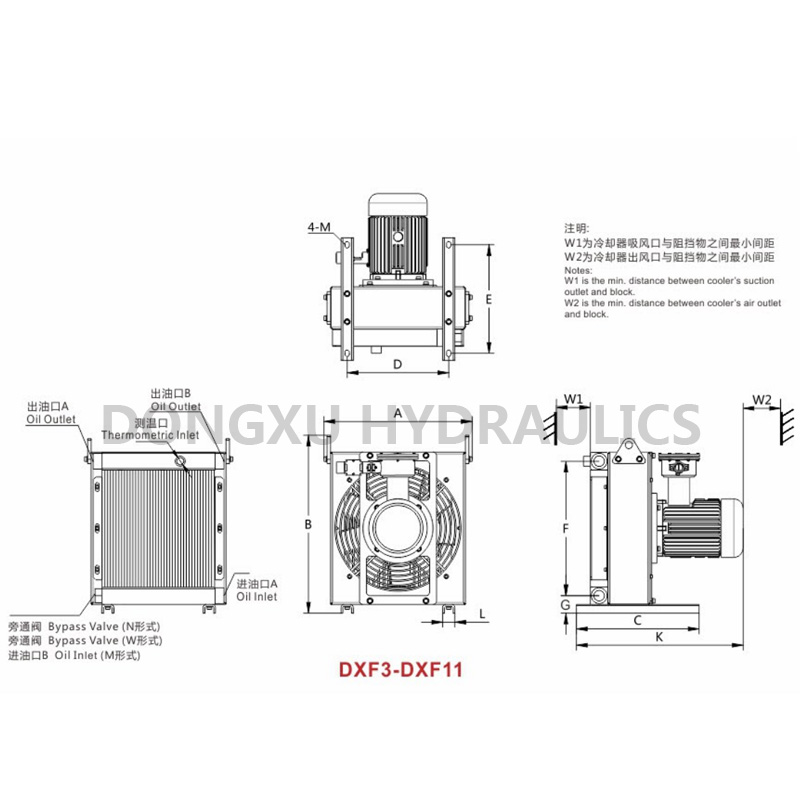

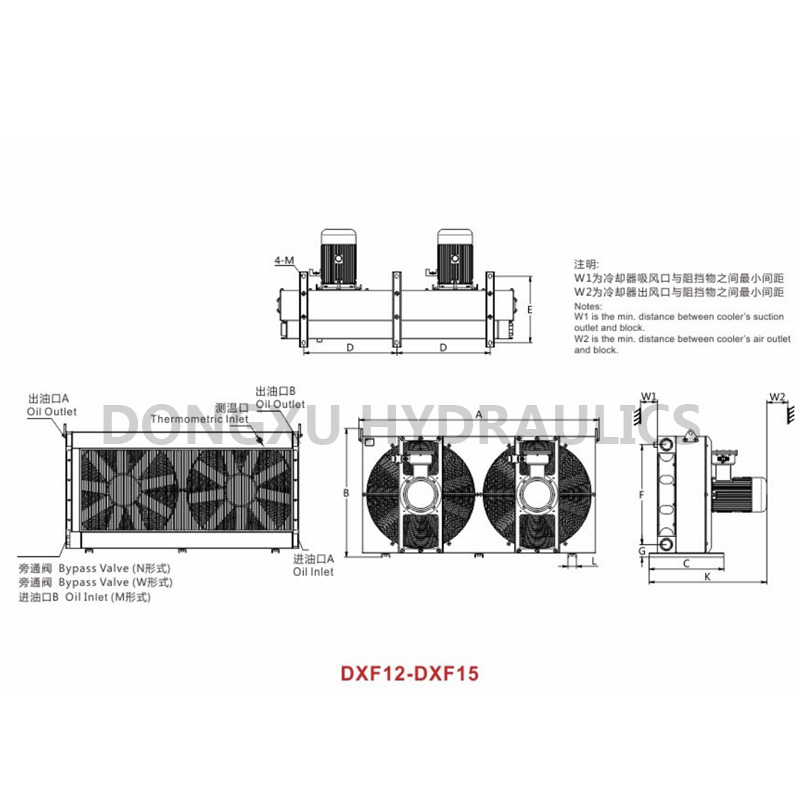

| A (mm±5) | 427 | 532 | 587 | 632 | 632 | 752 | 837 | 972 | 1082 | 1442 | 1642 | 1842 | 2047 |

| B (mm±5) | 503 | 563 | 603 | 623 | 623 | 763 | 919 | 1059 | 1208 | 763 | 913 | 1043 | 1193 |

| C (mm±2) | 350 | 350 | 350 | 450 | 450 | 450 | 500 | 600 | 600 | 450 | 500 | 600 | 600 |

| D (mm±2) | 290 | 390 | 450 | 490 | 490 | 560 | 645 | 700 | 700 | 560 | 645 | 700 | 800 |

| E (mm±2) | 310 | 310 | 310 | 400 | 400 | 400 | 450 | 550 | 550 | 400 | 450 | 550 | 550 |

| F (mm±5) | 384 | 434 | 475 | 495 | 495 | 634 | 780 | 920 | 1070 | 600 | 760 | 900 | 1050 |

| G (mm±5) | 50 | 55 | 55 | 55 | 55 | 55 | 60 | 60 | 60 | 75 | 70 | 65 | 65 |

| K (mm±10) | 531 | 550 | 570 | 631 | 651 | 691 | 721 | 721 | 768 | 741 | 741 | 741 | 768 |

| L (mm±2) | 40 | 40 | 40 | 45 | 45 | 45 | 55 | 55 | 55 | 45 | 55 | 55 | 55 |

| M (mm±2) | 12*18 | 12*18 | 12*18 | 12*18 | 12*18 | 14*22 | 14*22 | 18*25 | 18*25 | 14*22 | 14*22 | 18*25 | 18*25 |

| W1 | 180 | 200 | 220 | 250 | 280 | 320 | 380 | 400 | 500 | 320 | 380 | 400 | 500 |

| W2 | 380 | 400 | 450 | 500 | 550 | 650 | 750 | 800 | 1000 | 650 | 750 | 800 | 1000 |

| Note: * Cooling capacity: cooling power at △T=40℃. ** The noise value is measured at a distance of 1m from the cooler, which is only for reference. Because it is affected by the surrounding environment, medium viscosity and reflection. *** This table only takes AC380V-50HZ as an example. **** Motor grade: Energy consumption grade YE2, protection grade IP55, insulation grade F. (Other options please contact DONGXU) | |||||||||||||

Hydraulic machinery

Gear oil tank

| DXF | 8 | A3 | 5 | N | C | X | O | O |

| Cooler Type: Explosion-Proof Motor Drive Series | Plate Size: 3/4/5/6/7/8/9/10/11/12/13/14/15 | Voltage: A3=AC380V⬅Standard A4=AC440V A5=AC660V | Frequency: 5=50Hz⬅Standard 6=60Hz | Bypass Valve: N=Build-in⬅Standard W=External M=Without Bypass Valve | Oil Hole Direction: C=Side in side out⬅Standard S=Up in up out | Wind Direction: X=Suction⬅Standard C=Blowing | Temp. Controller: O=Without controller⬅Standard C3=Explosion-proof type | Heatsink Protection: O=Without protection⬅Standard S=Anti-Stone net |

Coal mining machinery

Hydraulic system circuit, independent cooling circuit and lubricating oil cooling system. For examples, coal mining machinery,mining machinery,hydraulic machinery,oil and gas power station,natural gas station,ship machinery,tunnel machinery,gear oil tank, and so on.

Natural gas station

Mining machinery

EXdIIBT4 GB is suitable for: factories with flammable gases, such as propane and ethylene. EXdIICT4 GB is suitable for: Plants with flammable gases such as hydrogen, propane and ethylene. EXdI Mb is suitable for: Coal mines, such as YB3 on the non-mining face and YBK3 on the underground mining face. EXtdb21 Db is suitable for: factories with combustible dust and combustible flying flocs, such as feed, textile, flour, cement and other places where dust is generated. Note: D2=YBK3 fan blade adopts carbon fiber explosion-proof blade.

Oil and gas power station

Tunnel machinery

Ship machinery